When mulling over options for the main landing gear on LSA aircraft, I think the Wittman-style gear is popular for good reason: Simple, light, no maintenance (except replacement of the "damper units"--the tires), and good ability to keep absorbing energy and protecting occupants even if pushed past the yield point of the materials.

If I recall correctly, Steve Wittman patented the tapered-rod style gear (spring steel?) and that this was later modified (by/for Cessna?) to flatter style gear legs. So it appears we have a choice of tapered rod or flat legs. Then, we have a choice of spring steel, aluminum, or titanium.

I'd be interested in input on the merits/experience regarding the various options.

Observations:

-- If the plane has a welded tube frame (or I can make them part of the engine mount), adding sockets for tapered rod legs would not be a significant amount of added work. I would think these would be lighter (more efficient use of material) than an option using flat legs.

-- At that point, there would be the choice of material. Titanium appears to be great from a weight perspective and the ability to absorb energy (I like the titanium legs on my Sonex), but just the raw material for two legs will cost several hundred dollars. Maybe spring steel would be more reasonably priced, more easily worked, and not too, too heavy. I'm >assuming< aluminum would be unsuitable in anything but very fat rods/tubes.

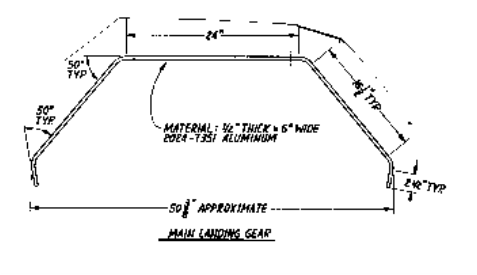

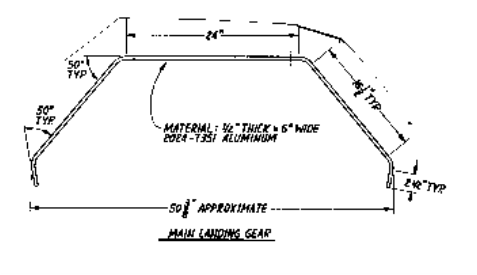

-- The very easiest answer appears to come in the form of the flat aluminum legs sold by O'Keefe Aero. These are the legs used on Sonereis, on the Thatcher CX4 and CX5, etc. Send them a check for about $525 - $700 and call it done. The smaller ones weigh about 25 lbs. The downside appears (to me) to be in the weight and the cost. Not pricey by airplane standards, but maybe something I could have bent at a machine shop and save some money. But, the weight would remain.

I need to get a copy of the Pazmany landing gear book to give this subject the study it deserves, but any tips or insight to get me started would be appreciated. Sources other than Pazmany worth looking at?

Thanks

If I recall correctly, Steve Wittman patented the tapered-rod style gear (spring steel?) and that this was later modified (by/for Cessna?) to flatter style gear legs. So it appears we have a choice of tapered rod or flat legs. Then, we have a choice of spring steel, aluminum, or titanium.

I'd be interested in input on the merits/experience regarding the various options.

Observations:

-- If the plane has a welded tube frame (or I can make them part of the engine mount), adding sockets for tapered rod legs would not be a significant amount of added work. I would think these would be lighter (more efficient use of material) than an option using flat legs.

-- At that point, there would be the choice of material. Titanium appears to be great from a weight perspective and the ability to absorb energy (I like the titanium legs on my Sonex), but just the raw material for two legs will cost several hundred dollars. Maybe spring steel would be more reasonably priced, more easily worked, and not too, too heavy. I'm >assuming< aluminum would be unsuitable in anything but very fat rods/tubes.

-- The very easiest answer appears to come in the form of the flat aluminum legs sold by O'Keefe Aero. These are the legs used on Sonereis, on the Thatcher CX4 and CX5, etc. Send them a check for about $525 - $700 and call it done. The smaller ones weigh about 25 lbs. The downside appears (to me) to be in the weight and the cost. Not pricey by airplane standards, but maybe something I could have bent at a machine shop and save some money. But, the weight would remain.

I need to get a copy of the Pazmany landing gear book to give this subject the study it deserves, but any tips or insight to get me started would be appreciated. Sources other than Pazmany worth looking at?

Thanks