Dean Westerburg

Active Member

- Joined

- Nov 2, 2020

- Messages

- 29

Looking for advice from those with more experience with VW's.

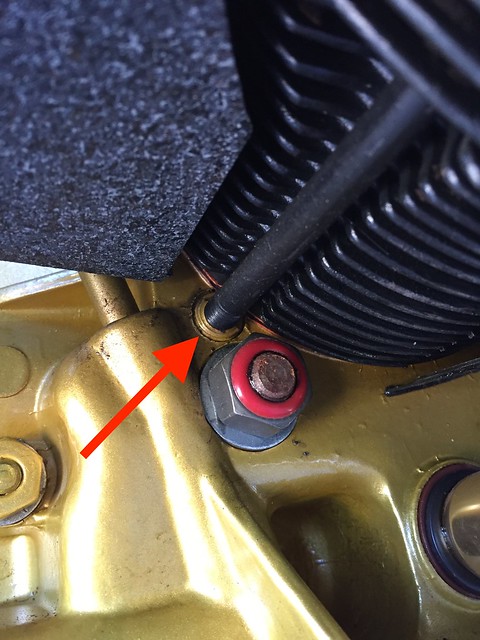

One of the 8mm studs that goes through the head on my HAPI 1835 has some stripped threads. THe last guy just put 2 nuts over it. I found it when checking the torque on the head. Can I replace just 1 of these or do I need to replace them all to be safe? Does anyone know if the HAPI 1835 had the "Case saver" inserts or do these thread right into the casting?

I also found a pushrod that looks like it has been gouged by the side of a pushrod tube, I assume due to mis-assembly and attempt to run at some point. Should the pushrods and pushrod tubes all be replaced at the same time, or is just 1 ok?

Do I need to replace the pushrod tubes if I remove the heads?

Thanks for your recomendataions.

One of the 8mm studs that goes through the head on my HAPI 1835 has some stripped threads. THe last guy just put 2 nuts over it. I found it when checking the torque on the head. Can I replace just 1 of these or do I need to replace them all to be safe? Does anyone know if the HAPI 1835 had the "Case saver" inserts or do these thread right into the casting?

I also found a pushrod that looks like it has been gouged by the side of a pushrod tube, I assume due to mis-assembly and attempt to run at some point. Should the pushrods and pushrod tubes all be replaced at the same time, or is just 1 ok?

Do I need to replace the pushrod tubes if I remove the heads?

Thanks for your recomendataions.