I've just come across a few things recently that might prove useful. I thought

a thread in which to post them might interest and attract some folks. Some of these machines might be cheap enough to reside in one's home shop, some exist only as plans for one to build from, and some are so expensive they would probably reside at a professional fabrication firm and we'd outsource the manufacture of something to them. As an example of the latter, I give this Figure G15 sheet-metal forming machine, although I hope some open-source heroes might design their own one day.

...

For the open source crowd, I offer three examples. Firstly, I give the Maslow 4, a 3-axis mill intended primarily for sheet plywood. If I understand correctly the latest iteration it uses toothed steel belts on a capstan to increase accuracy. Their webpage is v interesting.

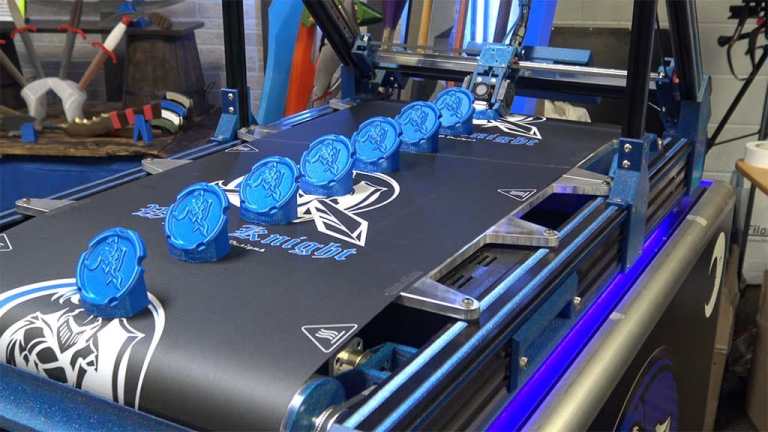

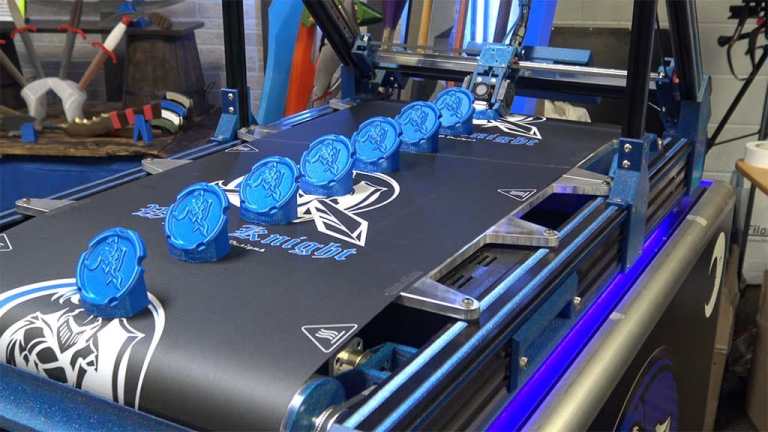

The second example is one of the largest "infinite z axis" 3d printers I've read of, and must be built from plans. I know, I'm a pedant too, but I think the x and y axes in 3d printing land are the two axes on the gantry, so the conveyor belt is the "z" axis. The White Knight has a build volume of 400mm *430mm * infinity. I'm not a compisites guy but I can't wait to just print the fuselage mold, print the wing molds, finish their surfaces, and crack on. Maybe run off all the fairings too. There's a separate thread in this forum highlighting the difficulty finding good software for these "infinite z axis" or "belt" printers:

I love the idea of electrical discharge machining; not least because the electricity doesn't care how hard the metal you want to machine is. I've always thought that aluminium bar would be annoyingly costly to machine down to a rough propeller shape. This might change with Rack Robotics' Betta Wire open source wire EDM. It doesn't yet do what I want, but the plans are published openly, so it may well change in capabilities over time. I know the gearbox nuts out there will want to make their own gears!

Lastly, open source in the literal sense only (but still super cool) is the Annin Robotics AR4 robot arm.

This is a real strategic-level tool, and while it might take more work to integrate into one's workflow, the potential for just "downloading an application" that let's the arm do [that thing you don't want to] is an amazing prospect. The AR4 is sold in kit form and one must build one's own.

Finally, my pal who welds clever things thinks laser-welding might be a game-changer ("I could teach a monkey to weld with one of those"). It is, however, very expensive at the moment.

Hope these are interesting to others. What cool new technology has anyone else noticed quietly growing somewhere, that might be ripe enough for us to exploit in some way?

Has anyone seen an affordable laser CAM tube cutting/coping tool?

a thread in which to post them might interest and attract some folks. Some of these machines might be cheap enough to reside in one's home shop, some exist only as plans for one to build from, and some are so expensive they would probably reside at a professional fabrication firm and we'd outsource the manufacture of something to them. As an example of the latter, I give this Figure G15 sheet-metal forming machine, although I hope some open-source heroes might design their own one day.

...

For the open source crowd, I offer three examples. Firstly, I give the Maslow 4, a 3-axis mill intended primarily for sheet plywood. If I understand correctly the latest iteration it uses toothed steel belts on a capstan to increase accuracy. Their webpage is v interesting.

The second example is one of the largest "infinite z axis" 3d printers I've read of, and must be built from plans. I know, I'm a pedant too, but I think the x and y axes in 3d printing land are the two axes on the gantry, so the conveyor belt is the "z" axis. The White Knight has a build volume of 400mm *430mm * infinity. I'm not a compisites guy but I can't wait to just print the fuselage mold, print the wing molds, finish their surfaces, and crack on. Maybe run off all the fairings too. There's a separate thread in this forum highlighting the difficulty finding good software for these "infinite z axis" or "belt" printers:

I love the idea of electrical discharge machining; not least because the electricity doesn't care how hard the metal you want to machine is. I've always thought that aluminium bar would be annoyingly costly to machine down to a rough propeller shape. This might change with Rack Robotics' Betta Wire open source wire EDM. It doesn't yet do what I want, but the plans are published openly, so it may well change in capabilities over time. I know the gearbox nuts out there will want to make their own gears!

Lastly, open source in the literal sense only (but still super cool) is the Annin Robotics AR4 robot arm.

This is a real strategic-level tool, and while it might take more work to integrate into one's workflow, the potential for just "downloading an application" that let's the arm do [that thing you don't want to] is an amazing prospect. The AR4 is sold in kit form and one must build one's own.

Finally, my pal who welds clever things thinks laser-welding might be a game-changer ("I could teach a monkey to weld with one of those"). It is, however, very expensive at the moment.

Hope these are interesting to others. What cool new technology has anyone else noticed quietly growing somewhere, that might be ripe enough for us to exploit in some way?

Has anyone seen an affordable laser CAM tube cutting/coping tool?

Last edited: